Monitoring of Shinkansen RC Viaducts

Background

The Shinkansen (Bullet Train) railway viaducts, built over 40 years

ago, are aging and are continuously subjected to increasing service

loads and severe earthquakes. The number of Reinforced Concrete (RC)

viaducts in service between Tokyo and Osaka alone is over 1000

blocks. This does not include the viaducts that connect other major

cities going north and south of Japan. Thus, there is a need for

retrofitting and repair, coupled with continuous monitoring of

existing viaducts in order to ensure safety and reliability of

transportation.

|

| Fig.1 Scanning LDV |

Measurement Systems

In the Bridge and Structure Laboratory, we are developing safe, smart

and fast monitoring systems that use high-technology sensors and

equipment. We are using laser Doppler vibrometers or LDV (single-point

and scanning types), servo-accelerometers, servo-velocimeters,

wireless tri-axial accelerometers and piezo-accelerometers for

measuring ambient, train-induced and impact vibrations. The data

collected are then processed using system identification techniques to

determine the dynamic properties of the viaduct and check if there are

any changes that may indicate damage.

|

| Fig.2 Servo-accelerometers for 3D Measurement |

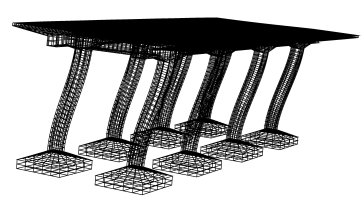

Finite Element Model

We are also using finite element modeling to derive models of the RC

viaduct. This is an important step because we are dealing with a real

structure that cannot be damaged for study. But using the FEM model we

can simulate damage at critical locations of interest and determine

how the dynamic properties of the viaduct change with increasing

damage. Figure 3 shows the global lateral mode shape of a finite

element model of a viaduct.

|

| Fig.3 Lateral Mode of an RC Viaduct |

|